Plastics : Deep analysis of plastic films

Types of Films:

By Material:

- PE (Polyethylene) Films : LDPE (flexible, clear, good moisture barrier), HDPE (stronger, better barrier properties), LLDPE (good stretch, puncture resistant)

- PP (Polypropylene) Films: Clear, stiff, good moisture barrier

- PVC Films: shrink properties, good clarity

- PET Films: very clear, strong, good barrier

- Nylon Films: high strength, good barrier

- Monolayer: Single material

- Multilayer: Multiple materials laminated together

- Coextruded: Multiple layers extruded together

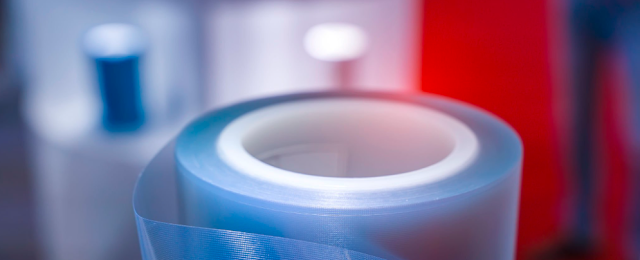

Blown Film:

- Plastic is melted and blown into bubble

- Air cools the bubble

- We then make a tube of film

- It can be slit into flat sheets

- Used for for PE films

- Plastic is melted and pressed through flat die

- The plastic is cooled on chill rolls

- It has a better clarity than blown film

- It has more more uniform thickness

- It is commonly used for PP and PET

PE (Polyethylene): A flexible, common plastic that comes in different densities. Used in plastic bags, bottles, and toys. Think of the material most shopping bags are made from.

PET (Polyethylene Terephthalate): A clear, strong plastic best known for beverage bottles. It's the material most soft drink and water bottles are made from.

Physical Properties:

- Thickness

- Strength

- Tear resistance

- Puncture resistance

- Stretch properties

- Clarity

- Moisture barrier

- Oxygen barrier

- Light barrier

- Gas barrier

- Sealing temperature

- Heat resistance

- Printability

- Machinability

Packaging:

- Can be used for food packaging

- Product wrapping

- For shipping materials

- For protective covers

- Greenhouse films

- Mulch films

- Silage bags

- Shrink wrap

- Stretch wrap

- Protective films

Shrink wrap is a plastic film that tightly wraps around objects when heated. Common for packaging electronics, food, and bundling items together.

Stretch wrap: A stretchy plastic film that clings to itself and is wrapped around items without heat, it is used to secure boxes on pallets or bundle multiple items together.

Testing processes:

- Thickness measurement

- Tensile strength

- Tear resistance

- Seal strength

- Optical properties

Tear resistance: How well a material resists ripping or tearing when force is applied.

Optical properties: The characteristics of how a material interacts with light, including, how clear it is, how shiny or glossy it appears and how it reflects light.

- Thickness variation

- Gels (unmelted particles)

- Poor sealing

- Film breaks

- Wrinkles

Application Requirements:

- Required strength

- Barrier needs

- Clarity needs

- Cost constraints

- Running speed

- Sealing needs

- Printing requirements

- Machine compatibility

- Recyclability

- Biodegradability

- Environmental regulations

- Carbon footprint

Process issues:

- Unstable bubble (blown film)

- Thickness variations

- Poor winding

- Surface defects

Unstable bubble (blown film): a defect in plastic film production where the balloon-shaped film being blown becomes unsteady or wobbly, like a soap bubble that won't maintain its shape.

Poor winding: it happens when film doesn't wrap evenly or smoothly onto a roll causing creases, wrinkles, or gaps in the roll.

- Weak seals

- Poor clarity

- Inadequate strength

- Barrier failures

- Temperature adjustments

- Line speed changes

- Raw material modifications

- Equipment maintenance

Sustainability:

- Bio-based films

- Recyclable structures

- Reduced thickness

- Compostable options

Bio-based films: plastic-like films made from natural, renewable materials (like corn, potato starch, or sugarcane) instead of petroleum.

Compostable options: materials that can completely break down into natural elements (like water, carbon dioxide, and biomass) over time without leaving harmful residues.

- Better barrier properties

- Smarter packaging

- Enhanced processability

- New polymer developments

Comments

Post a Comment